Understanding the Thickness Limit of Proton Exchange Membranes in Proton Exchange Membranes

- 逸风 黄

- Sep 30, 2025

- 4 min read

Introduction

Reducing the cost of hydrogen production via PEM water electrolysis requires focusing on lowering the ohmic losses, which dominate at high current densities (>2 A/cm²). Decreasing membrane thickness is a primary strategy to reduce proton transport resistance. However, pushing thickness below 50 μm necessitates balancing membrane resistance against critical factors like hydrogen crossover (safety), mechanical durability, and manufacturability. Safe operation requires nanoscale ion-conducting membranes with the following characteristics:

Extremely low hydrogen permeability (<1×10⁻⁹ cm²/s), very low area-specific resistance (<5×10⁻⁷ S/cm), and the ability to withstand acidic conditions for over 10,000 hours.

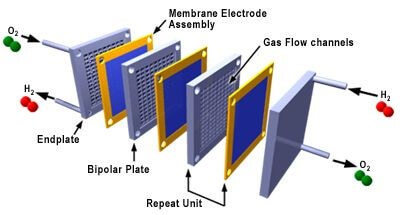

Compatibility with large-scale, cost-effective manufacturing and integration into defect-free Membrane Electrode Assemblies (MEAs). Achieving such membranes could significantly lower hydrogen production costs through efficiency and throughput gains.

The Impact of Membrane Thickness on Hydrogen Cost

The industry standard, Nafion 117 (178 μm thick), has an area-specific resistance (Rₘ) of about 120 mΩ·cm² at 50°C. While enabling high current densities (1.5-2 A/cm²) compared to alkaline electrolyzers, ohmic losses become prohibitive at higher densities. At 5 A/cm², ohmic loss can constitute 64% of the total overpotential, leading to low voltage efficiency (~54% based on LHV) and increased operational costs (Figure 1b, c). Calculations show that meeting the U.S. DOE's target of <$1/kg H₂ with electricity at $0.02/kWh is impossible with Rₘ > 50 mΩ·cm².

Reducing Rₘ to <10 mΩ·cm² is essential for efficient operation above 5 A/cm². Since the proton conductivity (σ_H⁺) of state-of-the-art PFSA membranes like Nafion is near its maximum, the primary path to lower Rₘ is reducing thickness (tₘ), as Rₘ = tₘ / σ_H⁺ (Figure 2). However, simply making Nafion thinner presents dilemmas: decreased mechanical strength, increased hydrogen crossover, and potential conductivity loss at very low thicknesses.

Hydrogen Crossover and Safety Limits

A critical safety concern with thin membranes is hydrogen crossover from the cathode to the anode, especially under pressure differentials (Δp_H₂) used to produce pressurized H₂. The steady-state H₂ flux (J_H₂) follows Fick's law and is inversely proportional to tₘ. The crossover rate (%CR), expressed as a percentage of H₂ production rate, must be kept below ~1% to maintain anode H₂ concentration under the 4% flammability limit in O₂ (Figure 3a).

For Nafion (P_H₂ ≈ 8×10⁻⁸ cm²/s) at Δp_H₂ = 14.8 bar and i = 1.5 A/cm², the minimum safe thickness is ~10 μm. This minimum thickness increases if the electrolyzer operates at lower current densities (e.g., with intermittent renewables), where lower O₂ production offers less dilution of crossed-over H₂. Integrating recombination catalysts can mitigate crossover but adds cost and complexity. Materials with inherently lower P_H₂ (e.g., 10⁻¹⁰ cm²/s) could enable safe operation with sub-micron thicknesses (0.1-1 μm).

Electronic Leakage

An ideal membrane must also block electronic conduction. Electronic leakage current, calculated via Ohm's law, should ideally be <1% of the total operating current to avoid significant efficiency loss. For a membrane with electronic conductivity similar to dry Nafion (σ_e ≈ 10⁻⁶ S/cm), the thickness can be reduced to ~1.4 μm before leakage exceeds 1% at 1.9 V (Figure 3b). Materials with higher σ_e require careful consideration.

The Key Membrane Descriptor: σ_H⁺/P_H₂

The analysis reveals that minimizing Rₘ while respecting safety limits depends on a fundamental material property: the ratio of proton conductivity to hydrogen permeability (σ_H⁺/P_H₂). The minimum achievable Rₘ (Rₘ,min) for a given maximum acceptable %CR is derived as:

Rₘ,min = (tₘ / σ_H⁺) = (Δp_H₂ / (%CR i F R_g T)) (1 / P_H₂) σ_H⁺

This simplifies to show that Rₘ,min is proportional to 1/(σ_H⁺/P_H₂). Therefore, maximizing σ_H⁺/P_H₂ is the key design goal, not just maximizing σ_H⁺ alone (Figure 4). A membrane with lower σ_H⁺ than Nafion can still achieve a lower Rₘ if its P_H₂ is sufficiently lower, allowing the use of extremely thin layers.

Manufacturing Challenges for Nanoscale Membranes

Achieving the promised performance requires fabricating defect-free membranes with nanoscale thickness (<1 μm, potentially down to 40 nm). Defects like pinholes or cracks can lead to catastrophic H₂ crossover via convection, far exceeding intrinsic diffusion-based permeation (Figure 5). Manufacturing must ensure exceptional thickness uniformity and the absence of defects over large areas. Scalable techniques like vapor deposition, used in semiconductors, may be necessary but must be adapted for MEA integration. The economic viability hinges on developing high-throughput, high-yield manufacturing processes.

Promising Material Directions

Overcoming the trade-off between H⁺ conductivity and H₂ permeability inherent in materials like Nafion (where both species transport through similar aqueous channels) requires decoupling the transport mechanisms. Promising avenues include:

Modified Polymers: Sulfonated hydrocarbon membranes or PFSA composites with additives like graphene oxide (GO) or silica can reduce P_H₂ by increasing pathway tortuosity without severely compromising σ_H⁺.

Inorganic Membranes: Dense proton-conducting oxides (e.g., doped perovskites, silica) offer very low intrinsic porosity, high mechanical strength, and thermal stability. While their σ_H⁺ at low temperatures is currently much lower than Nafion's, doping strategies (e.g., with phosphorous or sulfonic groups) have shown significant improvements. Thin (2-3 μm) silica-based membranes have been demonstrated in fuel cells.

Regulatory Drivers: Potential future restrictions on PFSA materials due to environmental concerns provide additional impetus for developing alternative membrane chemistries.

Conclusion

Nanoscale proton-exchange membranes (<1 μm) offer a pathway to drastically reduce ohmic losses, enabling high-efficiency PEM electrolysis at current densities 2-6 times higher than current standards. The key is to maximize the material descriptor σ_H⁺/P_H₂, which may involve using materials with lower absolute conductivity but vastly superior H₂ barrier properties.

The primary challenges are twofold:

Materials Development: Discovering and synthesizing materials that combine extremely low hydrogen permeability (<1×10⁻⁹ cm²/s), adequate proton conductivity, and long-term chemical/mechanical stability in acidic, oxidizing environments.

Manufacturing Innovation: Developing scalable, cost-effective processes for producing large-area, defect-free nanoscale membranes and integrating them reliably into MEAs.

Success in these areas could significantly reduce the levelized cost of hydrogen produced by water electrolysis, helping to meet ambitious clean energy targets.

References

[1] How Low Can You Go? Nanoscale Membranes for Efficient Water Electrolysis. ACS Energy Lett. 2024, 9, 1624-1632.

Comments