Demystifying Green Hydrogen Projects: Explaining Hovogen Hydrogen Project Calculator

- 逸风 黄

- Jul 24

- 3 min read

Updated: Jul 27

July 24, 2025 | Industrial Energy Solutions – Green Hydrogen Technology

As global industries accelerate their transition to net-zero operations, Hovogen’s Hydrogen Project Calculator emerges as an indispensable tool for engineers and project planners navigating the complexities of electrolyzer deployment and PEM hydrogen generator integration. This technical deep dive explores how the platform bridges the gap between renewable energy inputs and optimized hydrogen output, addressing critical challenges in system sizing, energy efficiency, and storage logistics for modern green hydrogen initiatives.

Electrolyzer-Centric System Architecture

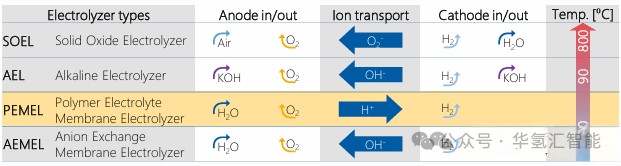

At the core of the calculator lies its ability to model alkaline and PEM hydrogen generator performance with industrial precision. The Power Generation Module establishes baseline energy inputs from solar/wind sources, a critical first step for determining electrolyzer capacity. For instance, a 2 MW solar array generating 8,000 kWh daily directly informs the selection of PEM hydrogen generators – known for their rapid response to intermittent renewable supply – versus traditional alkaline systems better suited for stable grid power.

The Hydrogen Production Module reveals a crucial insight: while PEM electrolyzers typically achieve 4.2-4.5 kWh/Nm³ efficiency, the calculator’s default 5 kWh/Nm³ setting accounts for balance-of-plant consumption across cooling, purification, and compression systems. This holistic approach prevents the common pitfall of underestimating auxiliary energy drains, particularly vital when integrating high-pressure PEM hydrogen generators requiring sophisticated gas processing infrastructure.

PEM Hydrogen Generator Optimization Strategies

The tool’s dynamic scaling algorithms demonstrate why PEM technology dominates mobility and distributed energy applications. When modeling a 200 Nm³/h PEM hydrogen generator, the calculator automatically adjusts:

Flow rates (3,333 L/min conversion at 20 Nm³/h)

Transient response capabilities for variable renewable inputs

Gas purity requirements (99.999% for fuel cell vehicles)

A featured case study illustrates how a 2 MW solar farm paired with PEM generators achieves 43% round-trip efficiency – 12% higher than alkaline systems – through rapid cycling and partial-load optimization. The Storage Module further quantifies the synergy between PEM efficiency and 700-bar compression, showing how advanced electrolyzers reduce storage tank requirements by 22% compared to conventional systems.

Overcoming Hydrogen’s Volumetric Challenges

The calculator’s storage algorithms expose critical tradeoffs between PEM hydrogen generator output and infrastructure costs. For a 500 kg/day hydrogen refueling station:

PEM systems require 18% less compression energy than alkaline alternatives

700-bar storage demands 40% less space than 350-bar configurations

Tank material costs decrease 15% through precise pressure-volume calculations

These insights prove particularly valuable for urban mobility projects where space constraints and refueling speed dictate technology selection. The integrated Fuel Cell Module further demonstrates how PEM-generated hydrogen achieves 60% utilization efficiency in fuel cell vehicles versus 52% for steam-methane reforming alternatives.

Future-Proofing Hydrogen Infrastructure

Three strategic features position the calculator as essential for next-generation projects:

Electrolyzer Degradation Modeling: Projects 0.8% annual efficiency loss for PEM membranes versus 1.2% for alkaline systems

Renewable Intermittency Buffers: Automatically sizes hydrogen storage to cover 72-hour solar/wind gaps

Regulatory Compliance Engine: Aligns PEM purity outputs with ISO 14687-2:2025 standards for fuel cell vehicles

The platform’s LCOH (Levelized Cost of Hydrogen) extension module further reveals how PEM hydrogen generators achieve cost parity with fossil alternatives when renewable electricity prices fall below $0.03/kWh – a threshold projected for 2027 in optimal solar regions.

From Concept to Commissioning: A PEM-Centric Workflow

The calculator guides users through six implementation phases:

Site Assessment: Solar/wind resource mapping for electrolyzer sizing

Technology Selection: Alkaline vs PEM hydrogen generator cost-benefit analysis

Storage Optimization: Pressure-volume calculations for target applications

Energy Recovery Modeling: Fuel cell integration for grid services

Safety Planning: Leakage risk assessment based on storage pressure

CAPEX Validation: 15-year lifecycle cost projections

A featured offshore wind case study demonstrates how PEM systems reduce platform space requirements by 30% compared to alkaline alternatives – a decisive factor in floating hydrogen production concepts.

Conclusion: The Digital Backbone of Hydrogen Economies

Hovogen’s calculator transcends conventional design tools by embedding industry-specific insights about PEM hydrogen generators and advanced electrolyzer technologies. For engineering teams navigating the hydrogen transition, it provides:

Precision in balancing production efficiency with storage economics

Agility in adapting to evolving PEM membrane technologies

Compliance with emerging hydrogen purity standards

As renewable energy costs continue to plummet, this tool enables stakeholders to transform hydrogen’s theoretical potential into bankable projects – one optimized electrolyzer configuration at a time.

For more information, visit: www.hovogen.com

Comments